Summary: A single oil analysis is a snapshot. The trend decides.

Pay attention Wear metals, Fuel dilution, silica, viscosity,

Water/glycol and Acid/base numbers (TAN/TBN). In case of anomalies: narrow down the cause, check in a targeted manner,

re-sampling after a short period of time.

Why oil analysis makes sense for ELA1 pilots

- Early detection of bearing, cylinder and valve wear.

- Evaluation of the Operating mode (cold run, high DA/heat, ‘lean of peak’, Mogas/Avgas).

- Well-founded TBO/On-Condition Decisions – Trends are evidence.

- Measure the effectiveness of interventions (time of ignition, prop balance, ring change).

How to Take a Usable Sample

- Warming up (> 70 °C), sample directly after parking.

- When leaving it Middle beam catch (not first/last drops).

- Clean laboratory bottle, gloves; Funnels only unique.

- Flight Hours, Oil Type/Brand, Refill Quantity indicate on the form.

- At the latest after 48 h send.

Tip: Always The same laboratory and The same oil use – this cleans up trends.

Key metrics – briefly explained

| block | Typical parameters | An increase means | Check immediately |

|---|---|---|---|

| Wear metals | Fe, Cr, Ni, Al, Cu, Sn, Pb | Fe Steel/Courses · Cr/Ni Rings/Valves · Al Pistons · Cu/Sn Bearing/bronze · Pb Bearing/AvGas residue | Compression/leak-down, endoscopy, slicing oil filter |

| contaminants | Si, Insolubles, Ash | Si = dust / dirt → intake air / leaks | Air filters, intake pipes, hoses/clamps |

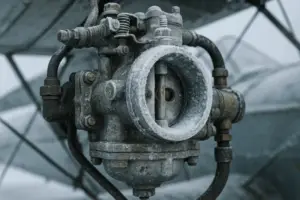

| Fuel & Water | Fuel dilution %, Water/glycol | Fuel dilutes oil (cold run, rich operation); Glycol in liquid-cooled Rotax | Cold start/hot run, carburettor/EFI, cooling circuit |

| Oil condition | Viscosity 40/100 °C, TAN, TBN | Viscosity ↓ Fuel/Wear · TAN ↑ Ageing/corrosion · TBN ↓ Additives consumed | Interval, operating profile, venting |

| additive | Ca/Mg/Zn/P | Varies per oil; Jumps = oil change/top-up | Match history |

Limit values are model- and laboratory-specific – more important than absolute numbers is the Comparison with Your Predictions.

Read lab report - in 5 steps

- Plausibility check: Oil type, runtime (h/day), refill quantity.

- Trend view: Comparison with 3-5 previous samples (similar runtime!).

- Cluster: Do e.g. Fe + Cr + Ni rise together? → friction partner/cylinder.

- Assign source: Use the table above (Pb+Sn → Stock, etc.).

- Action & Re-Test: define the measure, in 10-25 h Sampling again.

Typical findings & what you do

- Fe ↑ + Cr moderate ↑, Viscosity ↓ → Friction + fuel dilution.

Action: Test mixture/run-up, avoid cold running, oil change, re-test 15-20 h. - Si clear ↑ + Al easy ↑ → dust; React piston/raceway.

Action: Air filter/seal suction, endoscopy, re-test. - Cu + Sn ↑, Pb ↑ → bearing/bronze; Possibly AvGas effect.

Action: Cut open oil filter, check vibration/ignition, leak-down. - Fuel dilution > 2–3 % or Viscosity strong ↓ → a lot of short distance/rich.

Action: Adjust operating profile, carburettor/EFI setting, short interval. - TAN ↑ + Insolubles ↑ → Oil ages/humidity/maintenance.

Action: Interval shortening, dehumidification, longer warm runs, winter preservation.

Rotax Note (912/914/915): AvGas share > 30 % increases the need for maintenance; The interval between 25 and 50 h. Burp procedure and clean sampling are essential.

Decision Matrix (simplified)

- Single, slight abnormality (without trend) → continue flying, re-test in 15-25 h.

- Several metals rise together → Additional checks (compression/endoscope/filter cut), short interval, re-test.

- Strong jump + symptoms (vibration, oil consumption, metal in the filter) → ASAP workshop diagnosis.

- Glycol/water detectable → fly no further, fix cause.

From the hangar

- Prop balances: Fe/Cr trend flattens, CHT spread improves → measurable effect.

- Leaky intake gasket: Si peak in two samples; Normalized after gasket replacement.

- Training organisation: High fuel dilution + low viscosity; Profile adjusted → values stable.

FAQs

How often do you sample? At least for oil change; additionally after interventions or in case of abnormalities early.

Which runtime per sample? As constant as possible (e.g. 40-50 h), otherwise trends are difficult to compare.

When is a value ‘too high’? If it runs against your trend or multiple partners rise together. Laboratory flags are clues, not judgments.